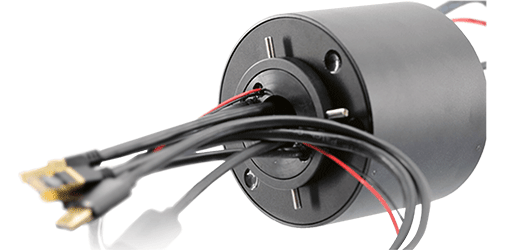

Industrial Slip Rings

What is a industrial slip ring?

Industrial slip rings are electrical devices that are used to transfer power, signals, or data between a stationary structure and a rotating structure. It consists of a stationary part (stator) and a rotating part (rotor) that are connected by conductive rings and brushes.

Industrial slip rings can be customized for specific applications, with a variety of features such as high speed, high power, high temperature resistance, and explosion-proofing. They are an essential component in many industrial machines and systems, ensuring reliable and efficient transmission of power and information.

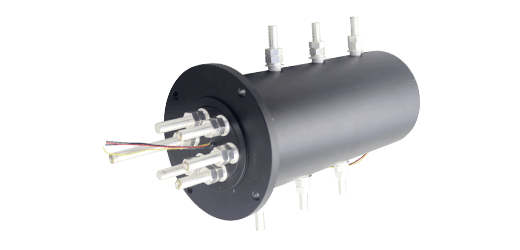

Ethernet Slip Rings

Ethernet slip rings are high performance slip rings for reliable ethernet data transmission. It is used as a special e...

View More >USB Slip Rings

The USB slip ring is specially designed for USB signal transmission. It can be used for transmitting the signal ...

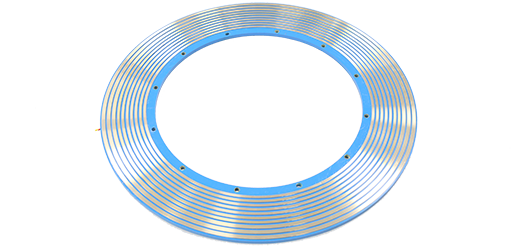

View More >PCB Slip Rings

The PCB slip ring is an flat disc electrical slip ring that consists of two parts: the ring surface and the brush as...

View More >High Current Slip Rings

High current electric slip rings are designed to high current devices. They are often used as rotary electrical connec...

View More >Large Through Bore Slip Rings

Large through bore slip rings are designed to forestry equipment. They are often used as rotary electrical connectors ...

View More >Pancake Slip Rings

Pancake slip ring ensures the current from a stationary wire keeps contact with a turning wire in machines that need to...

View More >Mercury Slip Rings

Mercury slip rings make use of mercury contact as a conductive, and, transference media. This allows for stable transf...

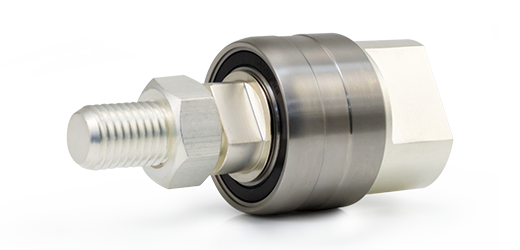

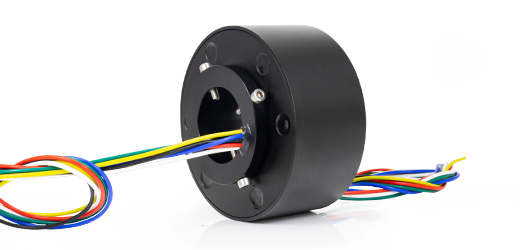

View More >Through Bore Slip Rings

Through bore slip rings are a high quality slip ring suitable for use in high speed machinery. It’s been designed wit...

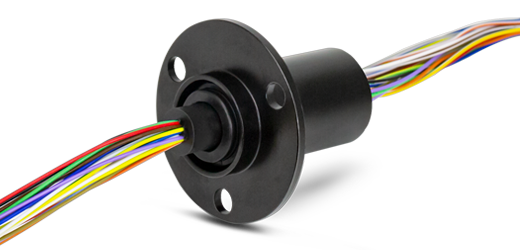

View More >Capsule Slip Rings

Capsule slip rings are the answers to electrical signal and transmission problems, built with creativity and originalit...

View More >Waterproof Slip Rings

A waterproof slip ring will guarantee protection from moisture, corrosion and is suitable for all types of underwater w...

View More >HD-SDI & Hdmi Slip Rings

HD-SDI slip rings are designed to aid the transfer of HD video signals as well as power and electrical signals. T...

View More >Learn More about Industrial Slip Rings

What are the applications of industrial slip rings?

Industrial slip rings are used in a variety of applications, including robotics, wind turbines, packaging machines, cranes, medical equipment, and many others.

They are ideal for applications that require continuous rotation while transmitting power and signals between the stationary and rotating parts.

How does an industrial slip ring work?

An industrial slip ring works by using conductive rings and brushes to transmit electrical power and signals from a stationary source to a rotating machine. As the rotor rotates, the brushes maintain contact with the conductive rings, allowing for the transfer of electricity and signals. The number of rings and brushes varies depending on the application and the amount of power and signals that need to be transmitted.

What are the advantages of using industrial slip rings?

The main advantage of using an industrial slip ring is that it allows for the transmission of electrical power and signals between stationary and rotating parts without the need for cables or wires that can break or tangle during rotation. This makes them ideal for applications that require continuous rotation.

Additionally, industrial slip rings are highly customizable and can be designed to meet the specific needs of the application.

What factors should be considered when selecting an industrial slip ring?

When selecting an industrial slip ring, several factors should be considered, including the required power and signal transmission capacity, the operating speed and temperature range, the level of protection required (e.g., dust and water resistance), and the overall size and weight of the unit.

How do I maintain and repair an industrial slip ring?

Maintenance and repair of industrial slip rings depend on the specific application and type of slip ring used. Generally, regular cleaning and inspection of the conductive rings and brushes are necessary to ensure proper operation.

In the event of a failure or malfunction, replacement of the damaged or worn components is necessary. It is essential to follow the manufacturer's instructions and guidelines for proper maintenance and repair.

Do you wholesale industrial slip rings?

Yes, We can. As industrial slip ring manufacturers, we can offer industrial electrical slip ring from 15a to 50a with affordable price in the market.

©2022 Orbinexus . All rights reserved Site Map

Pay Online

Pay Online Get A

Quote

Get A

Quote Deutsch

Deutsch