How a Rotary Joint works

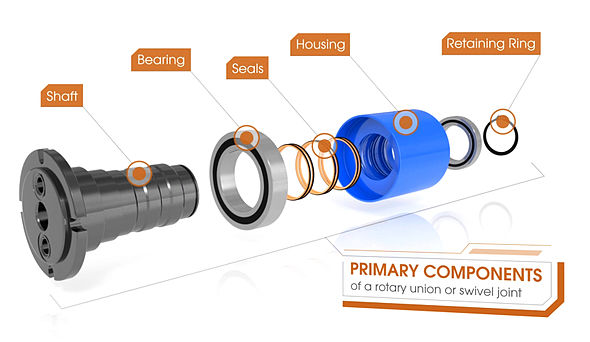

The basic design of a rotary joint includes a stationary part, a rotating part and a sealing mechanism. The stationary part is fixed to the stationary system, while the rotating part is fixed to the rotating system. The sealing mechanism is located between the stationary and rotating parts and ensures that the fluid or gas being transferred does not leak.

The sealing mechanism can be either a mechanical seal or a hydraulic seal. A mechanical seal uses a set of rotating and stationary parts that press against each other to create a seal. A hydraulic seal uses a set of O-rings or other seals that are pressed against a rotating shaft to create a seal.

When the rotary joint is in operation, the fluid or gas is transferred through the stationary part, through the sealing mechanism, and into the rotating part. The rotating part then transfers the fluid or gas to the rotating system.

Different types of Rotary Joint

I will now cover the different types of rotary unions so you can gain a better overall understanding of them and to aid your decision when purchasing one.

Hydraulic Rotary union

A hydraulic rotary union is specifically designed to transfer both fluid media as well as numerous channel air pressure. Hydraulic rotary unions are designed for rotary apparatus and they can provide safe and stable transmission for multi-passage air pressure and fluid media. Rotary unions enable the transfer of fluid media even when rotating at 360 degrees.

The newly designed hydraulic rotary union is now much more stable and dependable than older versions, the through bore design allows wires to pass through the device without any unwanted interference.

The Hydraulic Rotary Union allows for the transfer of media such as compressed air, oil, hot water, steam, nitrogen as well as many other types of fluid media, they can also be customized to better suit an individual’s needs. Typically, these types of rotary unions are found within robotic arms on machines and rotary tables but their uses are not limited to these applications.

Pneumatic Rotary Union

A Pneumatic Rotary joint is a rotary union which is designed to be operated by air or gas under extreme pressure, they are also able to be utilized for vacuum uses. Most people do not realize that most of the world around us and the way it works is largely based on pneumatics.

Pneumatic rotary unions can be found in applications such as a car wash or a drill head, with a car wash low-pressure water is fed through the supporting shaft of the rotary union into the brushes. Automatic car washes require rotary joints to transfer high-pressure water into the revolving brushes, thus cleaning the vehicle.

Within a drill head, high pressured air is shot into the end of the drill, causing the head to rotate 360 degrees rapidly and continuously. These are both an example of a pneumatic rotary joint application.

Fiber Optic Rotary Joint (FORJ)

A Fiber Optic Rotary Joint (FORJ) largely works in the same way for data and light signals, as a way of transferring considerable amounts of data in a short space of time across rotating parts.

Radio Frequency rotary joint (RF)

Radio Frequency Rotary Joints are the mechanical elements that are adopted to aid the transmission of radio frequency signals from a fixed part of a system to the parts which have the ability to move.

The types of fluid media which are used in a rotary joint

So, I have now discussed how a Rotary Joint works this brings me to all types of fluid media which are suitable for use within a rotary joint because you know, knowledge is power!

There are many different types of fluid media which can be used in a rotary joint, these are

Hydraulic Fluid

Air

Steam

Water

Coolants

Chemicals

Applications of Rotary Joints

Rotary joints are used in a wide variety of industries and applications, including:

Manufacturing

Rotary joints are used in manufacturing processes to transfer fluids such as water, oil, and steam. They are commonly used in rotary tables, milling machines, and other machinery that requires continuous fluid transfer.

Automotive

Rotary joints are used in the automotive industry for applications such as brake systems, fuel systems, and air conditioning systems. They are also used in robotic arms for automotive assembly.

Aerospace

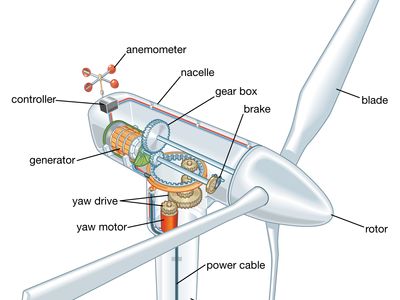

Rotary joints are used in the aerospace industry for applications such as satellite communications, radar systems, and missile guidance systems.

Medical

Rotary joints are used in medical applications such as laparoscopes, endoscopes, ct scanner, and MRI machines. They are used to transfer fluids and gases in medical procedures and imaging systems.

Radar

Rotary joints used within a radar system permit waves to be conveyed backwards and forwards from the fixed and revolving sections of the radar. During this transfer little to no signals can be lost. This makes rotary joints susceptible to use.

Rotary unions have the ability to pass both direct current and radio frequency signals with minimal loss of signal. The signals transferred can be as simple as 1 channel or as complex as 73 channels.

Purchasing a New Rotary Joint

There are a huge range of companies offering rotary joints in today’s market but not all of those companies are designing top of the range rotary joints, some are offering cheap low-quality rotary unions and this sadly has become common practice within the industry.

Having said that not all companies are behaving in the same way in this regard. Orbinexus for one have certainly bucked the trend. Orbinexus offers a wide range of rotary unions ranging from gas rotary unions to through bore rotary unions. They also offer great customized options should you require something different from what they have on site.

Drop them a message and see what they can do for you here

Conclusion

After reading this guide, you should now have a significantly better understanding of rotary unions. This guide, in short; was designed to help you understand the way in which they work as well as their many applications, the many different types of rotary unions and the components which comprise a rotary joint.

The overall aim was to set out this information in a natural, free-flowing way with the purpose of educating anyone who needed information about anything to do with a rotary joint.

If you enjoyed this content, get in touch and let us know!

Pay Online

Pay Online Get A

Quote

Get A

Quote