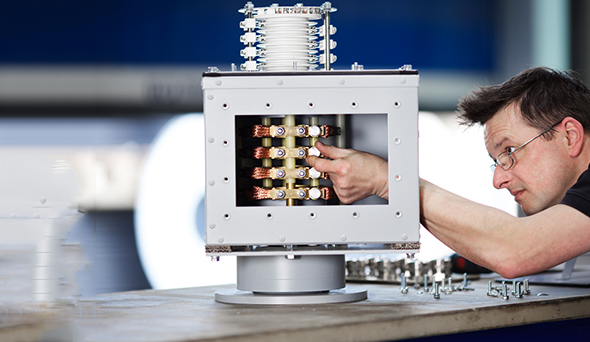

Electrical slip ring assembly

A electrical slip ring assembly allows for rotating signals to come to a stationary mean of collections.

Pancake slip ring assembly

When you have height restrictions, a "pancake" ring - also known as a "flat" or "plate" ring - may be the best solution. We build custom versions of these rings using 4 to 50 conductors to include the desired center hole size.

Pancake slip ring assembly: In this arrangement, the brush holder is mounted separately on the host and positioned correctly over a separate ring plate.

Pneumatic slip ring assembly

A pneumatic slip ring assembly is a device used to transfer pneumatic air under pressure or vacuum from a fixed inlet to a rotating outlet, maintaining and isolating the fluid connection as it rotates 360°.

Thermocouple slip ring assembly

Thermocouple slip ring assemblies are well suited for low level electric potential transfer where thermocouples need to be connected to rotating parts.

Rotary table slip ring assembly

We can take the rotary table slip ring assembly that you need to plug into the power and communication ports without having to hard wire it during assembly.

Propellor shaft brush slip ring assembly

Propeller shaft slip ring assemblies are designed to provide extremely low resistance electrical contact between the propeller and the shaft of a boat. They are required because electrical continuity through the boat's transmission to the propeller shaft is usually very poverty.

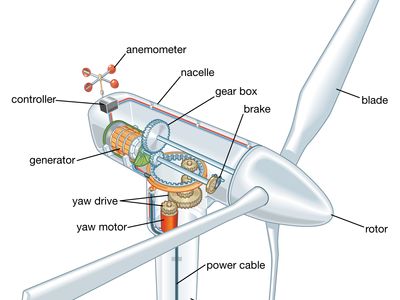

Crane slip ring assembly

The crane slip ring assembly maintains effective and efficient operation that make an electrical connection from a stationary object to a rotating assembly.

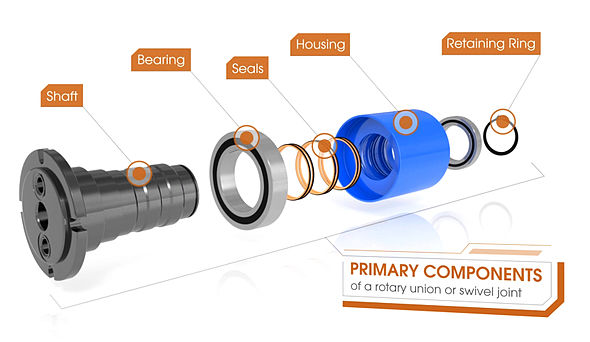

Hydraulic slip ring assembly

Hydraulic slip ring assembly typically include housings, shafts, bearings, rings and seals. This separate assembly prevents leaks, errors and damage to stationary and rotating parts.

Through bore slip ring assembly

Through bore slip ring assembly with a hole in the center. The rotor part rotates and the stator part is fixed for general installation, but it's also ok with stator part.

Custom slip ring assembly

For the past decade, we have been designing and manufacturing both standard and custom slip ring assemblies for a diverse range of industrial applications. Our team's expertise and engineering experience enable us to create robust slip ring assemblies that meet the demands of your most demanding applications. We can take your custom slip ring assembly from an initial concept to a finished product!

Our engineering department employs the latest solid modeling software to design custom slip ring assemblies. Our staff members have years of experience in all aspects of slip ring design.

Do you only require a few unique components, or perhaps just one? No problem! We have an extensive range of flexible machining centers and CNC lathes and mills that can build your custom ring. Feature CAM CAD/CAM software controls our machines, which enables us to go from concept to manufacturing swiftly. To ensure that you receive your custom slip rings quickly, our experienced assemblers work in flexible cells. We perform our in-house metal fabrication, welding, and part finishing to manage quality and lead times.

In addition to custom slip ring assemblies, we can integrate a variety of other devices such as

When you require an enclosure for your custom slip rings, we offer a broad selection of potential solutions. We have designed and manufactured numerous unique enclosures and can build one to fulfill your specific needs.

Conclusion

After reading this guide, you should now have a better understanding of slip ring assemblies from manufacturers. In short, this guide is designed to help you understand how they work and their many applications, as well as the many different types of slip ring assemblies.

If you like this content, please contact us and let us know!

Pay Online

Pay Online Get A

Quote

Get A

Quote